Analytical cookies are used to know how website visitors interact with the website. These cookies help present information on metrics the amount of visitors, bounce level, targeted traffic source, and so forth. Advertisement advertisement

It's a lightweight colour, comparable to beech wood, and is a snap to work with, permitting many finishes and variations. Rubberwood is additionally proof against warping and cracking, making it a functional option for each day use.

1 fascinating issue about rubberwood is that it is an eco-welcoming solution mainly because it is constructed from trees that have already served their reason in producing rubber.

This written content has been through meticulous truth-checking by our staff of internal authorities. Obtain a further idea of the large editorial benchmarks we copyright on our Site right here.

Even though drying, rubberwood has a tendency to warp and twist, producing it to distort just before comprehensively drying. Even so, it might be really long lasting and durable after it’s seasoned.

As rubberwood is a slightly moderate Variation of the normal hardwood, robust or brutal impacts can most likely crank out dents on it. It truly is proposed that you should put in rubberwood furniture particularly spots of your home where by it’s not extensively very hot or dry.

By repurposing rubber trees for timber, it helps to mitigate the carbon footprint related to their disposal.

Regardless if you are a seasoned woodworker or simply just commencing during the industry, Understanding with regards to the wood manufacturing course of action is crucial.

These are frequently prolonged, flat planks — a great shape for even more processing. Below, computerised techniques are involved to ensure utmost generate from Every single tree.

Understand that rubber wood furniture, like some other wooden furniture, isn't going to like cleansing solutions with abrasives, potent substances which can hurt the surface area and permanently spoil the looks of the furniture.

Then, wipe away the paste by using a damp cloth and dry the surface thoroughly. When the stain persists, you may need to refer to knowledgeable furniture restorer.

Immediately after staying chopped down, the wood is transported to your committed lumber drying mill. A lot of these amenities is usually substantial — they’re where the felled tree starts its genuine transformation to website getting an excellent timber product or service. A variety of essential factors take place:

With this period, automated technological innovation makes sure that merchandise are made to high requirements, Conference the market’s technical specs for power and toughness.

Industrial wood processing is a complex, multi-stage process that utilizes Highly developed technological innovation to transform Uncooked wood into concluded items with superior efficiency and precision. This creation procedure is divided into vital phases, each created to enhance high-quality and processing speed.

Jaleel White Then & Now!

Jaleel White Then & Now! Michael Fishman Then & Now!

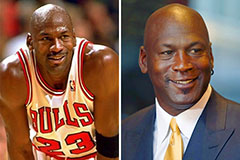

Michael Fishman Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now!